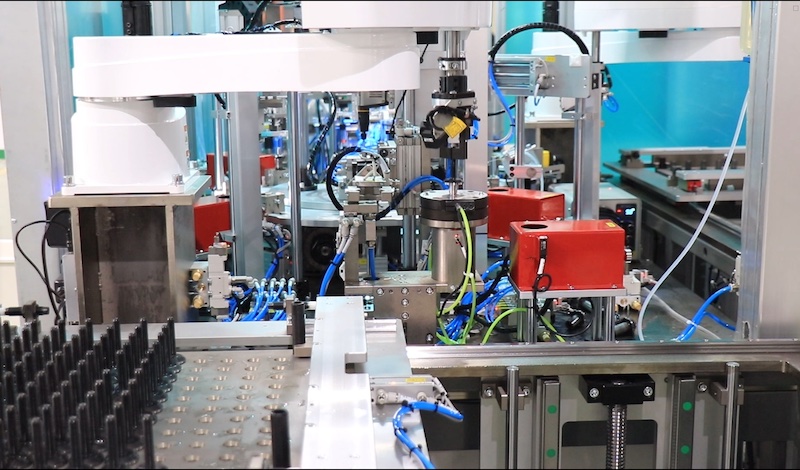

The assembly line is independently developed by our company, realizing the automatic assembly and testing of micro-torque products.

1、the whole line adopts the silo feeding method, only twice per shift, saving the cost of manual feeding;

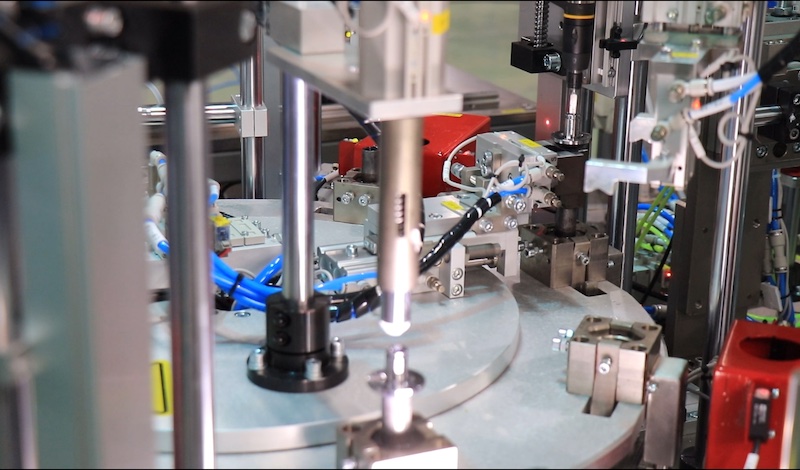

2、the tightening axis with precision mechanical tooling, the whole tightening is less than 0.04N.m.

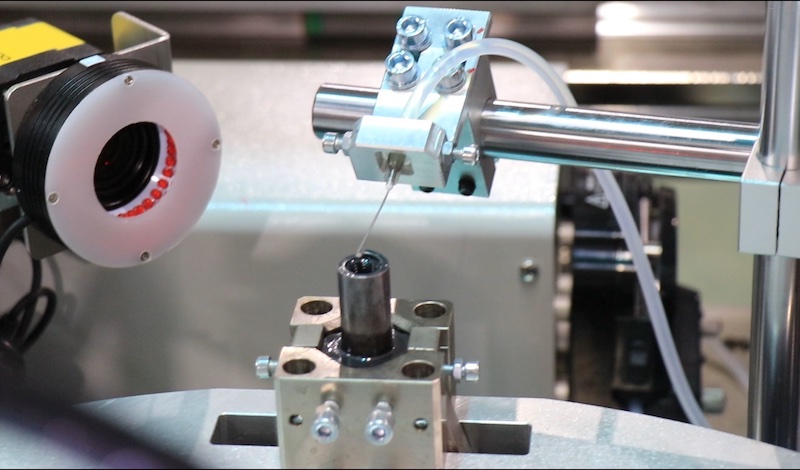

3、the product stop judgment and needle roller bearings use precision visual inspection, and the corresponding picture is bound with the product information code, to facilitate subsequent inspection.

4、The whole line adopts flexible mechanism to ensure accuracy and prevent damage to parts. All data is traceable and unique during the assembly process.